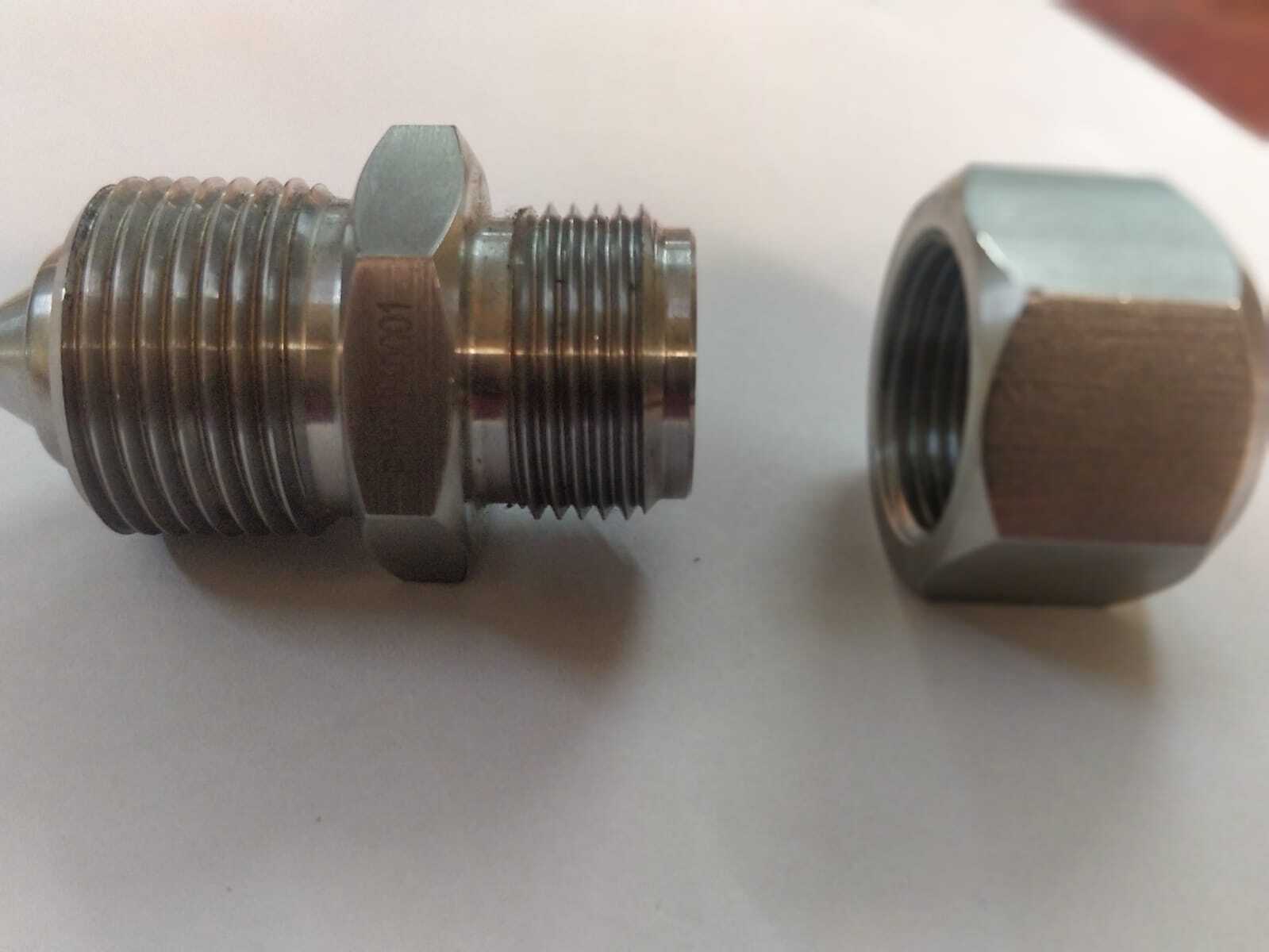

Lubricating Fittings

Price 1000 INR/ Box

MOQ : 10 Boxes

Lubricating Fittings Specification

- Connection Type

- Screw-in

- Working Pressure

- Up to 4000 PSI

- Type

- Grease Nipple / Lubrication Fitting

- Application

- Industrial lubrication systems, automotive, heavy machinery

- Quantity Per Pack

- 100 pieces

- Usage

- To supply grease or lubricant to moving parts

- Thread Size

- 1/8 BSP, 1/4 BSP, M6, M8, M10, 1/4 NPT (custom sizes available)

- Material

- Steel

- Surface Finish

- Zinc Plated

- Temperature Range

- -20C to 120C

- Head Type

- Straight, 45, 90

- Packaging Type

- Box

- Corrosion Resistance

- High

Lubricating Fittings Trade Information

- Minimum Order Quantity

- 10 Boxes

- FOB Port

- Tuticorin

- Payment Terms

- Paypal

- Supply Ability

- 1000 Boxes Per Week

- Delivery Time

- 1 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- by carton box

- Main Export Market(s)

- South America, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- As per standards,

About Lubricating Fittings

Purchase sizzles with value when you select our Lubricating Fittings-an unprecedented paragon in grease delivery for moving parts. Crafted from lofty quality steel and zinc plated for robust corrosion resistance, each box contains 100 pieces designed to excel under heavy loads, up to 4000 PSI. Compatible with various thread sizes (including BSP, NPT, and custom options), they cater to versatile industrial, automotive, and machinery lubrication requirements. Straight, 45, and 90 head types ensure perfect fitment, while a wide temperature tolerance affirms dependable performance. Supplied by a leading Indian manufacturer, distributor, and exporter.

Superior Lubrication for Industrial & Automotive Applications

Lubricating Fittings are engineered for use in industrial lubrication systems, automotive assembly lines, and heavy machinery. These fittings seamlessly supply grease or lubricant to moving parts, ensuring optimal equipment performance and longevity. Their primary advantages include exceptional corrosion resistance, high working pressure, and a diverse selection of head types, fitting various installation needs. Easy to use with screw-in connectivity, they constitute a highly reliable and competitive solution, making them indispensable in demanding operational environments.

Global Exports & Domestic Reach with Flexible Service

Lubricating Fittings command significant traction in markets across Europe, Asia, Africa, and the Middle East. We welcome enquiries with transparent asking prices and offer sample policies for select applications. All orders are promptly dispatched, with swift fulfillment ensuring order completion within agreed timelines. In India, our products enjoy a strong presence in major industrial centers, ensuring accessibility and timely delivery for both large-scale and small-batch requirements. Experience seamless service, whether exporting or ordering domestically.

Superior Lubrication for Industrial & Automotive Applications

Lubricating Fittings are engineered for use in industrial lubrication systems, automotive assembly lines, and heavy machinery. These fittings seamlessly supply grease or lubricant to moving parts, ensuring optimal equipment performance and longevity. Their primary advantages include exceptional corrosion resistance, high working pressure, and a diverse selection of head types, fitting various installation needs. Easy to use with screw-in connectivity, they constitute a highly reliable and competitive solution, making them indispensable in demanding operational environments.

Global Exports & Domestic Reach with Flexible Service

Lubricating Fittings command significant traction in markets across Europe, Asia, Africa, and the Middle East. We welcome enquiries with transparent asking prices and offer sample policies for select applications. All orders are promptly dispatched, with swift fulfillment ensuring order completion within agreed timelines. In India, our products enjoy a strong presence in major industrial centers, ensuring accessibility and timely delivery for both large-scale and small-batch requirements. Experience seamless service, whether exporting or ordering domestically.

FAQ's of Lubricating Fittings:

Q: How do I select the suitable head type for my lubrication fitting application?

A: To choose the appropriate head type (straight, 45, or 90), assess the available space and direction of grease flow needed for your equipment. Straight heads suit accessible areas, while angled heads provide a solution for tight or awkward spaces in machinery.Q: What process ensures the high corrosion resistance of these fittings?

A: These fittings undergo a zinc plating process, which forms a protective layer over the steel surface. This finish safeguards against oxidation and rust, extending the operational life of each fitting even in harsh working environments.Q: When is it ideal to use custom thread sizes for lubricating fittings?

A: Custom thread sizes are recommended when machinery or lubrication points deviate from standard BSP or NPT threads. By using custom sizes, you can ensure a secure connection and optimal grease delivery, tailored specifically to unique systems.Q: Where are these lubricating fittings typically installed?

A: They are commonly installed in industrial lubrication systems, automotive manufacturing lines, heavy construction machinery, and maintenance workshops. Their adaptable design allows for integration into a broad range of grease and lubrication applications.Q: What is the benefit of a high working pressure in these fittings?

A: A high working pressure capacity (up to 4000 PSI) means these fittings can deliver lubricant effectively under demanding operational conditions, reducing maintenance frequency and improving the reliability of machinery or vehicles.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free